Bending Test Machine: An In-Depth Guide to Flexural Testing Equipment

The bending test machine serves as the gatekeeper to the territory of flexural strength and durability in terms of material testing. According to the work at hand, whether it is metal, plastics, composites, or wood, this one crucial piece of testing equipment makes it possible for engineers, manufacturers, and researchers to assess the behavior of materials subjected to stresses and bending forces. This blog shall be your very ultimate guide to flexural testing equipment, understanding working principles, types of machines, and their applications in the industries. After which, you’ll have gained ample knowledge about the very reasons why bending tests are so crucial for the assurance of real-world reliability and performance of materials. So, let us plunge into the science behind bending and see how this technology plays out in innovation and quality control. Find more info now.

Bend Test Overview

The bend test is considered a primary test to judge the flexibility, strength, and ductility of materials. When force is applied to a specimen until it bends or fractures, the bend test tells us how the material acts when put under stress. This information helps in identifying potential weak points so that the structure is ensured for a particular load, and it also helps in predicting how it will perform in other applications. These tests are very much common in fields like construction, aerospace, and manufacturing for ensuring material quality and safety.

What is a Bend Test?

The bend test in mechanical testing methods helps to shed light on dwell and breaking points and is otherwise used to place materials under bending stresses without breaking or undergoing conspicuous cracking. This test gives information about elongation, elasticity, tensile properties, etc., and thus are handed down as deciding factors as to whether a material is suitable for specific structural applications.

The process usually entails clamping the specimen with supports and an applied force by use of a plunger to a preset angle or until the specimen fails. Predominantly, the bend tests are the three-point bending and the four-point bending. The load in the three-point bending applies at a single point in the center, but in the four-point bending test, the load is supplied by two points, thus evaluating the behavior of the material in a broader sense.

A bend test will typically be used in a metal fabrication plant to determine whether steel-based materials can stand up to quality standards relating specifically to welding of joints covered by ASTM (American Society for Testing and Materials) standards. For ductile materials, standards such as ASTM E290 give the details for accomplishing the test and how to interpret the results to ensure uniform evaluation.

The bend test produces data such as bending strength (MPa), the maximum bending angle prior to failure, etc. For example, mild steel can generally be bent to an angle of 180° without cracking, proving very ductile. Such pieces of information help in guiding industries such as building bridges, making automobiles, and designing pipelines in selecting materials that satisfy their safety-based and performance-based expectations.

Importance of Bend and Flexural Tests

Bend and flexure tests are the primary methods used for testing the gamut of stress performance of a material used in investigation, fabrication, or quality checks. The test includes using the material for some experiments that define its flexibility, stiffness, and resistance to deformation, and in cases where they involve value for structural application or durability, these properties become indispensable.

The bend test is used, for instance, to find out the flexural modulus, or, in other words, flexural stiffness of the material that is important in construction, so that the structure can resist bearing loads and deflecting to a high degree. Concrete, which has flexural strength ranging approximately from 3 to 5 MPa, is subjected to three-point bending to determine the capacity of the concrete beams and slabs to withstand tensile stress.

The same kind of testing on carbon fiber composites usually reveals that they do stuff better in terms of strength-to-weight ratio, with flexural strength values usually bigger than 1000 MPa, which is really important for aerospace and automotive materials that require design for light weight and high durability.

Plastic and polymer materials, on the other hand, are tested for their limitations in bending and flexural applications, mostly used in consumer engineering products and industrial applications. For example, polycarbonate materials have high flexibility and impact resistance and typically have a flexural strength value between 90-130 MPa. This data is used to confirm that these materials may be effectively used for applications including protective equipment, as well as in electronic housings.

In essence, bend and flexural testing offers reliable input as regards to material behavior under stress, thereby forming the foundation relating to how safer, efficient, and longer-lasting structures and products are designed across various industries.

Applications of Bend Test Machines

By crucially analyzing material properties and structural behaviors under stress, the bend test machines have found applications across various industries. By applying bending forces, these machines permit engineers and scientists to study whether the strength, flexibility, and durability under certain bending conditions of these materials are sufficient for their intended use.

The domain of construction and civil engineering

Bend tests are especially important when we talk about reinforced concrete, steel, or composite beams for use in building works, materials conforming to safety standards and structural regulations. A large-scale example of this would be testing steel reinforcement bars for ductility and yield strength in construction projects to ensure that the real-life conditions they will have to endure do not exceed these values. Technically advanced bend testing machines have large capacities, even to test beams, pipes, and girders.

Automobile Industry

Bend test machinery ranks among the apparatus necessary in testing vehicle parts like suspension parts and chassis components which must undergo antecedent loads and stresses. Depending on their formulation and treatment, high-grade aluminum alloys that are normally tested in this branch would generally have bending strengths within the range of 200-300 MPa. This is to ensure these components stand up to the safety and performance requirements, thereby facilitating better vehicle efficiency.

Aircraft Industry

They need bend tests to find materials that are considered lightweight and exceptionally strong in material composition, among others, such as titanium alloys and carbon fiber composites, which get subjected to extreme pressure and bending forces in operation. By means of testing, these machines make sure that structural parts such as aircraft wings and fuselages can endure rigorous conditions without compromising performance.

Electronics and Consumer Goods

To test their resistance against manufacturing and daily use, circuits, plastic housings, and other electronics components are subjected to resistance testing. The tests are performed, for example, on polycarbonate plastics used in smartphones and laptops to resist flexural stresses that would otherwise cause fractures or deformations. More advanced instruments for bend testing provide the test parameters with precision, allowing the manufacturer to improve longevity of the products and a user’s safety.

Energy and Pipelines

Bend test machines serve to test some important parts in pipelines and structural steel for the energy sector. Materials like high-strength steel for pipelines have to maintain their integrity under extreme thermal and mechanical stresses, with bend strength values mostly hitting those between 300-500 MPa.

The ability to simulate bending forces of the real world allows bend test machines to perform a vital role in guaranteeing product reliability, safety, and innovation across these and lots of other industries.

Types of Bend Test Machines

Bend test machines include universal, 3-point, 4-point, semi-guided, and pure bending systems, each designed for specific material testing needs.

|

Type |

Feature |

Use Case |

|---|---|---|

|

Universal |

Multi-purpose |

Various materials |

|

3-Point |

Single load point |

Flexural strength |

|

4-Point |

Dual load points |

Fracture analysis |

|

Semi-Guided |

Controlled bending |

Angle testing |

|

Pure Bending |

Uniform stress |

Precision analysis |

Universal Testing Machines

The main function of these testing machines is to check material properties under various conditions of testing-for tension, compression, bending, and the like. Thus, because of their universal nature, they find their applications in the aerospace, automotive, construction, and research lab sectors, where testing accuracy is vital.

Modern-day Universal Testing Machines have high-precision load cells and extensometers, so they measure forces accurately, sometimes with ±0.5% tolerances. They cater to a vast range of test capacities with anything from 1 kN to more than 2,000 kN for lighter materials such as plastics or composites, up to heavy-duty structural steel. Many of them also provide software that analyzes the data, giving the user real-time stress-strain curves and detailed insight into the material’s performance.

Other new-generation UTM capabilities include cyclic and fatigue testing, i.e., real-world conditioning to assess material behavior under repeated loads. This is of added importance to those industries where the parts are expected to bear long-term stresses: bridges or flight-critical aerospace parts. Their ability to integrate automatic controls and digital feedback loops helps in the repeatability and faster completion of testing sequences, thus helping in minimizing human error.

Bearing in mind the perfect fusion between its performance and technology, the UTMs are still one of the most vital tools available to advance material research and truly make sure that commercialization meets the tightest safety and reliability standards.

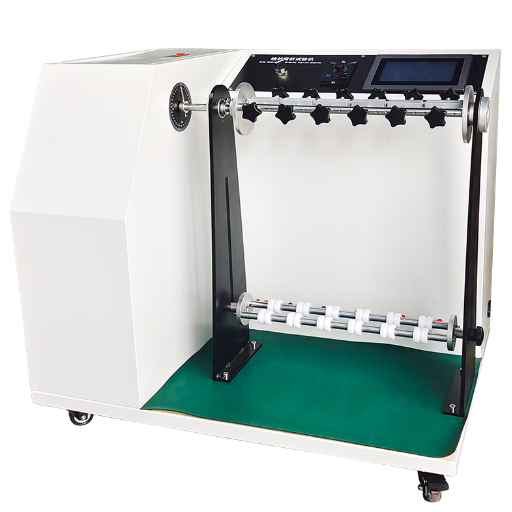

Dedicated Bend Test Machines

Bend test machines are especially made to instrumental in flex tests that find the independent gad tension and flexural or fracture properties of materials. Such machines are indispensable when testing the performance of metals, composites, polymers, and ceramics, which find their way into construction, automotive, and aerospace applications.

Lead engineers have bestowed upon bend test machines a modernity with sophisticated sensing technology to collect data in real time, such as force-displacement curves, maximum loading capacities, and stress versus strain relationships. Some common examples include the standard three-point bend setup that engenders a force at the middle of the sample while supporting it on the ends. This helps in finding out how hard the material will be when subjected to bending forces without fracturing. Technological advances now allow testing machines to be programmable with controls for adjusting test parameters, such as span, force application speed, and temperature, to better simulate real sample conditions.

Apart from this, such machines are usually outfitted with laser or optical-based extensometers that measure deformation accurately to the micrometer level. The accuracy of measurement comes in handy in various fields that require precise quality control, such as measuring the toughness of bridge supports or that of high-strength alloys for aircraft structures.

The capacity to accept a variety of sizes, ranging from thin sheets to almost very bulky beams, accordingly has made such modern, dedicated bend test machines an integral part of materials testing with respect to international standards like ASTM E290 and ISO 7438. With features such as user-friendly software interfaces and automated reporting systems, an operator can easily evaluate his own data, ensure consistency across tests

Comparison of 3-Point and 4-Point Bend Test Configurations

3-point bend tests are simpler and focus stress at the midpoint, while 4-point tests distribute stress evenly for more accurate material analysis.

|

Aspect |

3-Point |

4-Point |

|---|---|---|

|

Setup |

Single load point |

Dual load points |

|

Stress |

Focused at midpoint |

Distributed evenly |

|

Accuracy |

Moderate |

High |

|

Complexity |

Simple |

Complex |

|

Best Use |

Brittle materials |

Ductile materials |

Testing Standards and Methods

Bend testing should ideally be conducted following internationally accepted testing standards to ensure consistency and reliability. The two major standards in use are ASTM E290 and ISO 7438. ASTM E290 defines the methods to carry out bend tests on metallic materials with regard to their ductility and resistance to cracking. Likewise, ISO 7438 provides a general method for determining the plastic deformation properties of metallic test pieces. Both standards clearly instruct on the preparation of samples, testing arrangements, and acceptable results so as to witness an accurate return and fair comparison of results between two testing environments.

ASTM Standards for Bend Testing

ASTM E290 is still the governing standard defining ductility and cracking susceptibility of metals subjected to bending stress. The standard mentions two basic testing methods: free bend and guided bend. In a free-bend test, a panel to be tested is bent without any external constraints; guided bending involves using a die and plunger system to enforce bending at a predetermined angle. Both methods are intended to simulate actual stresses that the metals would face and evaluate their structural integrity.

Important factors for ASTM E290 include the bending angle, the radius of the mandrel employed for testing, and the orientation of the test specimen (for example, longitudinal or transverse to the rolling direction of the material). For instance, recommended mandrel ratios usually lie between 1.5 and 4 times the thickness of the specimen, depending on the nature of the material. The apparatus must be graded to focus the force evenly so the test results can be trusted.

An important consideration is the alteration of ductility from one material to another tested by this standard. High-strength alloy steels would typically tolerate bending radii much smaller than those allowed with softer-type materials such as aluminum-that would show their first signs of necking or localized weaknesses during testing. When combined with a quantitative approach (surface cracking) and metrics, a fuller picture emerges as to how a given material fares under bending stress.

A degraded version can harm industrial sectors particularly in automotive, aerospace, and construction applications, wherein materials must deform for the safety and reliability criteria to be met.

ISO Testing Procedures for Flexural Tests

ISO testing procedures for flexural tests are designed to measure and standardize materials’ resistance to bending forces. ISO 178 is one of the standards frequently cited in the determination of flexural properties for rigid and semi-rigid plastics. However, the procedure calls for subjecting a sample placed on two supports to a force at the midpoint so that it bends, fractures, or reaches a specified amount of deformation.

Flexural stress, strain, and modulus are the key parameters that are measured during such tests. The properties thus measured give a fairly complete picture of how the material behaves for mechanical stresses in actual applications. For plastics, the ISO 178 procedure describes testing conditions such as specimen dimensions, loading rates, and temperature-whether of room or controlled-ensuring the reproducibility or data-generation methods are comparable.

The apparatus for flexural testing that complies with ISO consists of universal testing machines, which, in turn, carry a unique flexural fixture. This fixture makes sure of exact alignment and that the force is distributed equally onto the test specimen. The speed of testing varies between 1 mm/min and 10 mm/min, thereby adjusting to the expected feed rate of the material under test.

The fields of application of the testing standard are enormous. For example, automotive manufacturers test dashboard items to make sure that they are flexible enough so that they do not crack under internal stress. On the other hand, aerospace engineers need to take flexural data in selecting composite materials that will satisfy the load conditions encountered in flight.

Modern-day modifications in the ISO testing procedure involve the use of some measuring gadgets for strain measurement accuracy. Such tools-optical extensometers and digital strain gauges-provide feedback in real-time, thus allowing dynamic data analysis to be performed on the measurements.

Defining Test Methods for Material Testing

Material testing includes several methodologies; a given process is selected to study a certain property. The different tests determine how much the material can withstand a force; for example, the material may be tested for how strong or flexible it is under hardening conditions. Among tests, tensile testing perhaps holds the highest regard since it obtains very crucial information on the performance of materials under forces attempting to separate them into two; the parameters measured include ultimate tensile strength, yield strength, and elongation at break.

Innovation in material testing has eventually brought automatic and forceful precise apparatus to automate, to render further exact measurements. Taking tensile testing for example, universal testing machines of multiple heads can now load force in the magnitude of several hundred kilonewtons; thus, this provides a never-before opportunity for the testing of super-strong materials such as steel alloys and carbon fiber composites. Impact tests, including Charpy and Izod, test for toughness with great effectiveness by measuring the energy absorbed in fracture. For reference, aerospace-grade titanium alloys are very tough, and their impact resistance exceeds 30 Joules during standard Charpy tests.

Surface indentation methods of hardness measurements include Brinell, Rockwell, and Vickers tests. These are to be used in the industries that require abrasion-resistant materials. Rockwell scales are used to group metals such as stainless steel into categories according to their hardness. Vickers testing serves a technical objective of gleaning more information about microhardness and is best suited for thin layers or coatings.

The new technologies enhance both precision and accuracy. Digital Image Correlation (DIC) systems and non-contact laser extensometers became indispensable in materials testing laboratories. These systems allow for full-field strain measurements and help eliminate errors arising from any physical interaction with the specimen. Along with this instrumentation, modern software platforms allow one to process the data in real time and generate complete material profiles for a wide array of applications in aerospace, construction, and renewable energy industries.

Material testing remains a crucial indicator of quality, performance, and safety of materials applied in various fields. By pursuing the most contemporary methodologies and tools, the industries have adequate assurance in selecting materials best optimized for their intended use, thus pushing the limits of engineering and design.

Components of Bend Test Machines

Bend testing machines have various major parts to run an accurate and reliable method of material testing:

- Support Rollers- Fixed points at which the material sample is placed and supported during testing.

- Loading Nose- The central device applying force to the material sample to cause it to bend.

- Drive Mechanism- Controls the speed and movement of the loading apparatus to guarantee a steady application of force.

- Load Cell- Measures the amount of force applied to the sample accurately.

- Control System- A control system made of a digital interface or software to set parameters, monitor and record results.

Together these components test for the flexibility, strength, and resistance to deformation of a material when a stress is applied.

Fixtures Used in Bend Testing

Bend testing involves specialized fixtures which grant materials the treatment of a testing method. Such a fixture is required to clamp the test specimens so as to subject them to a force causing bending under controlled, standardized conditions. Typically, the fixtures may be:

Three-Point Bend Fixture

Two supports are positioned a fixed distance apart, the loading pin or roller applying force at the specimen’s midpoint. It finds its usage in the testing of materials like metals, plastics, and composites. For example, it has been found that the three-point bending is suitable for establishing flexural strength, which is calculated on the basis of the maximum stress that a material undergoes at the time of testing.

Four-Point Bend Fixture

This type of fixture transmits force through two loading pins, balancing stress across the material. It is more advantageous for testing brittle materials like ceramics since the stress concentration at any single point is thus decreased. Four-point bending tests have been quoted to give more reliable information when materials are subjected to evenly distributed loads.

Compression-Bending Fixture

These fixtures apply both compression and bending and are therefore suitable for civil engineering applications where beams or concrete samples have to be tested. Compression-bending tests are more suitable for hybrid materials because of the information derived in terms of flexural and compressive behavior.

Adjustable Bending Fixture

This fixture is designed for flexibility, allowing for different specimen sizes and testing parameters. Adjustable fixtures are often used by industries for non-standard materials or prototypes to ensure testing consistency regardless of unconventional sample dimensions.

Micro-Bending Fixture

Micro-bending fixtures enable precise micro-scale testing through highly sensitive systems for thin films or fine wires. Specialists regard such fixtures as being necessary to materials for electronics and nanotechnology, wherein even slight deformations may seriously affect performance.

When employed correctly, these fixtures ensure that materials of all types are subjected to accurate and reproducible measurements. Continuous improvement in the design of the fixtures, such as automation of alignment and load-distribution processes, is changing for better the reliability and the speed by which bend tests are carried out all over the world.

Test Samples and Specimen Preparation

Bend testing outcomes must be accurate and consistent for which proper sample preparation is required. Samples must be cut, shaped, and if required polished to remove surface defects that can propagate during testing better than those defined by standards. The dimensions of specimens are equally important and should strictly follows ASTM E290 or ISO 7438 as depending upon the specific testing needs. Both standards set a specification related to thickness, width, and length to maintain uniformity and comparative evaluation.

From the point view of the test reliability, material homogeneity and condition are paramount. For example, surface treatments or preheating can be applied to metallic materials to assure that their properties are those that exist in the normal applications. For similar reasons, composite materials may require strict lay-up orientations and curing procedures to simulate their structural properties as intended.

During specimen preparation, newer methods use high-level machinery, like laser cutting, and automated grinding, to achieve further precision. Some recent findings have suggested that these techniques reduce the time used for specimen preparation by up to 35% whilst simultaneously giving a much better finish to edges with a lower amount of variability between test specimens.

Negative attention to pre-test sample storage is just important. Atomic storage factors include some form of temperature maintenance within controlled limits and specified values of humidity as a must, lest the test materials may unwittingly go through any changes, like oxidation or moisture absorption-from the time they are taken from storage and prepared for testing. The strict observation of these sample preparation steps yields reproducible, strong results to the engineers and scientists to lead them to novel design of materials.

Bend Fixtures: Types and Functions

I classify bend fixtures with respect to their different designs and usages. Common types of bend fixtures are three-point, four-point, and lateral-bend fixtures. Each type performs a different function—for example, three-point bend fixtures test the flexural properties of materials, while four-point bend fixtures give a more uniform stress distribution on the specimen under test. On the contrary, lateral bending is used to ascertain a material’s resistance to twisting or side loading. Thus, by analyzing these special roles of the fixtures, I select one that would offer him the most appropriate test for accurate and reliable analysis.

Frequently Asked Questions (FAQs)

What is a bending test machine used for?

The bending test machine puts mechanical properties into evaluation by forcing the object under bending loads. Flexural strength, modulus of elasticity, and other properties under bending stress are subjected to observation and analysis for quality control during manufacturing.

How does a flexural test work?

In flexural tests, a test fixture holds a test specimen while a load is applied as per the test method on specified points, usually by some three- or four-point bending method. The test machine detects the extent of deformation and the stress exerted on the material until the material ends in failure, offering important data regarding its flexural strength and modulus of rupture.

What are the various bend test methods?

There are numerous bend test methods: three-point bending, four-point bending, and guided bending. These methods differ primarily in the manner in which the applied load acts and the support conditions of the specimen, thereby allowing the investigation of the flexural behavior of materials in different environments or setups.

What do bending tests give us in the definition of the importance of an elastic modulus?

The tests are considered important for determining the elastic modulus since they indicate the stiffness a material displays when side-loaded by bending loads. The greater the modulus of elasticity, the lesser the material tends to deform and the more structural it is considered.

What are the specifications used for bending tests?

Several standards have been devised for bending tests, including ASTM and ISO standards. The standards specify the procedures, requirements for conducting the tests so that results become dependable and reproducible under different sets of equipment and laboratories.

What materials can be tested on a bending test machine?

A bending test machine can be used to test almost any material, apart from polymers, metals, and composites. The machine is engaged in testing the resistance of various materials to a bending force and in measuring their flexural strength and ductility.

What is the function of a test fixture in bending tests?

It is very important that during the bending test, the testing assembly secures the specimen while the load is being applied. Precise alignment in the direction of the applied load and distribution of forces is the most necessary; otherwise, inaccurate test results will be obtained, obstructing the comprehension of the bending behavior of materials.

How do materials respond to repeated bending?

Repeated bending leads to fatigue-encompassing weakening of materials. Bending testing machines simulate conditions under repeated bending to show how materials perform under cyclic loads, aiming at assessing the service life and performance of materials in a given long term.